Lifting Equipment: What Is Best For A Heavy Load?

Lifting equipment is something that a lot of companies running industrial operations, plants, factories and construction jobs need to shift large loads. After all, the tonnage involved with different machinery parts and fixtures is just too much for human labor to safely handle. So, when it comes to moving large parts, you're going to need some pretty powerful gear. But what exactly is the best equipment to use in such a situation? And, just as importantly, where can you find that equipment? We'll answer both those questions, and more, in this article.

The Reliable Hydraulic Jack

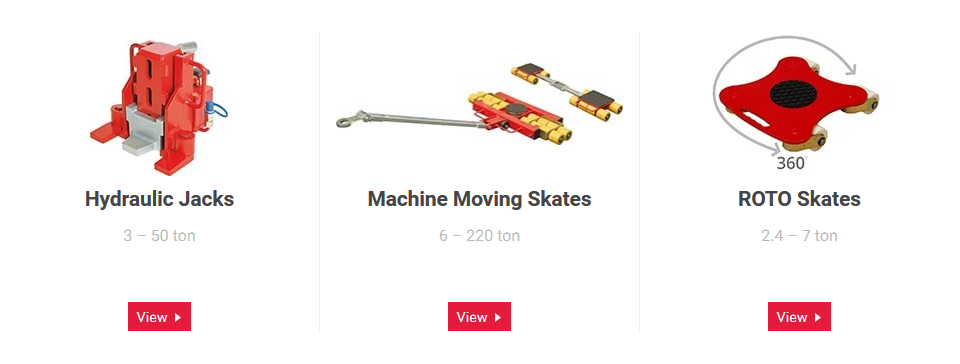

Without a doubt, the number one lifting equipment that is used in a variety of settings is the hydraulic jack. This system has many benefits – one of which being its small size and its ability to operate in limited space. The hydraulic jack lift works by using a pump plunger to force an incompressible liquid – such as oil – into a cylinder. This process, along with the use of a discharge valve and a suction valve ball, comes together to build pressure in the cylinder via a chamber. It is that pressure that allows large loads of above 50 tons to be lifted. These hydraulic jacks can come in a range of different varieties. You will often see smaller models in shop work or garages for the purposes of lifting vehicles to allow mechanics to get underneath and handle repairs. Similarly, this is the case when an engineer needs to get underneath large machinery in a factory to make repairs. They can also be used to lift the likes of elevators in buildings. There are many industrial models that can truly handle larger equipment and vehicles – including the likes of the 'toe jack'.

Understanding The Hydraulic Toe Jack

The hydraulic toe jack provides an even safer and more secure way of handling and lifting equipment. Additionally, the design of the toe jack means that it is far faster at lifting than other jack alternatives. Even in a garage setting, it is wise to have a toe jack on hand. This is because there may be a time when a larger vehicle requires repairs – such as a coach or a truck. Traditional 'trolley' jacks can only manage a few tons at most, so it is worth considering having a toe jack on standby. Another benefit of the toe jack is its fantastic ground clearance. Whilst most heavy-duty jacks using hydraulic power struggle to get underneath objects with low ground clearance, the thin, sturdy claw at the bottom of the jack allows it to have as much ground clearance as the traditional trolley jack. So not only does the toe jack have the benefits of a trolley jack, it also has the power of an industrial hydraulic jack. As such, it is clear that the toe jack is the best option to have when it comes to lifting heavy equipment. So, that covers lifting; but what about moving that equipment?

Moving With Machine Skates

When it comes to moving heavy loads that have been lifted by hydraulic jacks, machine skates are the perfect solution. Machine moving skates can lift everything from just a couple of tons – the weight of a standard manufactured American car – to an astonishing couple of hundred tons. This makes them ideal for those who are looking to move large machines and equipment of an industrial size. They work via the use of compressed air to generate pneumatic power. When combined with a hydraulic jack, they are a perfect way to lift and move heavy loads without any major disruption or additional requirements. For example, a fork lift requires a qualified fork lift driver. However, the use of skates and a jack don't require any specialized training – just a health and safety run-through that covers proper use. Cranes and similar systems also require high ceiling space. So, skates are a great solution to these problems. But without any sort of steering implement, skates can potentially be unsafe – particularly when trying to maneuver such large equipment and machinery. So how do you steer these heavy loads with skates?

Using A Machine Dolly

Using a machine dolly alongside skates and a jack is the fastest, simplest and easiest load moving solution around. This is because load moving dollies allow for heavy machinery and equipment to be steered. Without such a mechanism, skates could easily get out of control and would also require multiple people around the load to ensure that the load is going in the right direction. For extremely large loads, a dolly can also be attached to the back of a small truck or vehicle to allow the load to be moved with relative ease. The durability of the bars used on a good-quality dolly don't just allow for a load to be pulled; indeed, a load can be pushed too. The problem, however, is made redundant if you use dollies and skates that have swivel pads that allow for 360 degree turning underneath the load. This means that the dolly's load isn't set on a linear back and forth path; but can be manipulated in all different directions – making it incredibly flexible in areas that have restricted space. So, with it now being clear which load moving system is best for heavy equipment and machinery, it's time to find a supplier of such equipment. Which company produces the best, most reliable lift equipment? Well, one such producer of this equipment is HTS Direct, LLC.

HTS Direct, LLC Produces The Best Lifting Equipment

At HTS Direct, LLC, we are dedicated to providing our customers with the safest, most reliable and best quality lifting equipment in the United States today. Whilst our company is new within the US market, we have been operating in Germany and the UK for nearly 20 years. During that time, we have refined and defined what quality load moving equipment looks like. We've opened shop here to bring our efficient, German-engineered products to our American customers via a domestic distribution service specifically tailored to the USA. Get in touch with us today by calling us on (616) 591-3945 or via sales@hts-direct.com. For more information on our products, just visit https://www.hts-direct.com.